The wide-ranging technical knowledge and depth of experience offered by our staff make FCL an excellent choice for assistance with the development of novel engineering projects, especially where success depends on the satisfactory resolution of complex design challenges affecting several integrated components.

A recent example of this was FCL's involvement in the development of a facility capable of converting plastic waste into virgin feedstock for the production of new plastics.

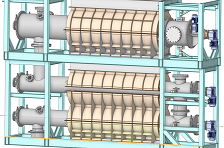

At the heart of this facility lies a three-stage pyrolysis reactor, through which the plastic waste is moved via screw augers. Flue gas from a burner is used to externally heat the reactor chambers to temperatures in excess of 800ºC, giving rise to thermal cracking of the plastic into hydrocarbon vapour. The vapour is subsequently passed to a set of tuneable condensers to separate product fractions by dew point, while remaining uncondensed gas is captured and used as fuel for the burner to produce a self-sustaining process.

FCL were presented with a design concept by their client and tasked with developing and substantiating a detailed design, including production of fabrication drawings. FCL first undertook a comprehensive data gathering exercise and used this to produce a set of mechanical data sheets addressing each of the principal items of equipment, which provided a firm starting point for all subsequent activities. Design was then performed in phases, starting with high-level conceptual design to establish basic scantling dimensions and material selection, before moving on to detailed design.

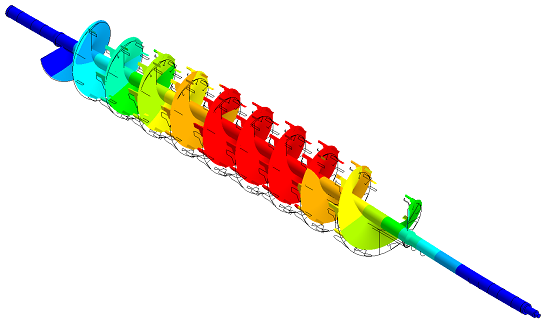

One of the most challenging aspects was found to be the development of the screw augers, which needed to be capable of efficiently moving the plastic through the chambers while offering sufficient strength and longevity at the extreme operating conditions to which they were exposed. The design process was based on a combination of spreadsheet-driven calculations and linear elastic stress analyses carried out using ANSYS professional finite element software, with consideration given to the influence if creep, fatigue and creep-fatigue interaction. This demonstrated a requirement for the use of exotic nickel alloys, which further complicated the process due to a lack of suitable published data on the fatigue resistance of such materials.

FCL's activities also extended to the design of appropriate bearing and sealing arrangements, the identification and specification of a specialist surface hardening process to provide the shaft with sufficient wear resistance, and the selection of suitable gearbox / electric motor combinations for each screw auger based on predicted torque requirements.

Once the mechanical data sheets and preliminary fabrication drawings had been produced, FCL also took on the task of identifying and approaching potential suppliers / fabricators for the reactor chambers, screw augers and ancillary equipment, permitting the production of a detailed capital costs report for these items.