One of FCL’s longest client relationships is with a leading oil refinery cyclone manufacturer who nearly thirty years ago decided to outsource their mechanical design work to FCL.

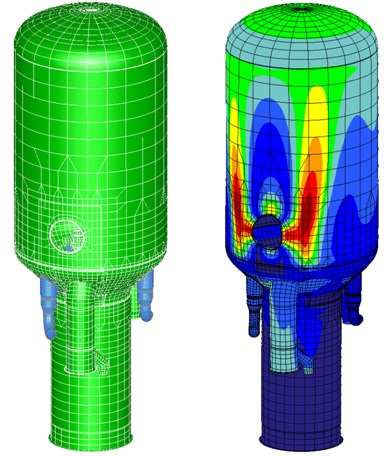

The cyclones are commonly installed inside FCCU reactor and regenerator vessels and can be subject to long term temperatures of nearly 800°C under external pressures develop by the process through-flow.

Throughout the relationship, FCL’s expertise has underwritten the continuous improvement of the cyclone design methods employed, enabling our client to demonstrate a technical advantage over their competitors and thus enhance their reputation in the industry sector in which they operate. This has led to the award and successful execution of turnkey refinery revamp projects in which entire new reactor and regenerator vessel head assemblies, including the internal plenum and cyclones, are designed and built for installation during refinery shutdowns.

FCL have similar long-standing relationships with a number of high profile oil refinery and chemical plant operators to whom we regularly provide engineering support ahead and/or during plant outages. Such work often involves the assessment of the significance of defects and/or excessive corrosion found during outage inspections, but can also include the design of replacement equipment when specific assets reach the end of their useful life.

Case studies covering some of the work that we have carried out for clients in the petrochemical industry can be viewed by clicking on the links below.