FCL have long enjoyed a close working relationship with two of the UK's acknowledged leaders in the provision of submarine rescue solutions.

This has led to involvement in the design of new and re-conditioned rescue submersibles and associated ancillary equipment for the UK, Australian, Indian, Chinese, Singaporean, South Korean, Vietnamese and Swedish navies.

FCL have played an integral role in the development of ten out of the last eleven rescue submersibles engineered in the UK

(LR5, LR7, DSAR 5, DSAR 6, DSAR 650 (2-off), DSAR 500, DSAR 500-AC (2-off) and LR11)

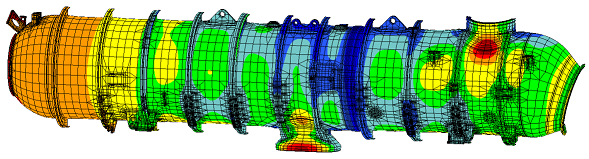

with the level of our involvement progressing from substantiation of existing designs through to complete turnkey solutions including front end engineering, weight optimisation, load case development, detailed design and fabrication drawing production.

Case studies covering work carried out in the marine industry can be viewed by clicking on the links below.

FAQs

Added January 2026.

We have very significant experience in submarine design, and have a close working relationship with two of the UK's acknowledged leaders in the provision of submarine rescue solutions.

Thanks to these relationships, we have played an integral role in the development of ten out of the last eleven rescue submersibles engineered in the UK, with the level of our involvement progressing from substantiation of existing designs through to complete turnkey solutions including front end engineering, weight optimisation, load case development, detailed design and fabrication drawing production.

We have also carried out design and research oriented work related to larger submarines.

We have been involved in the design of new and re-conditioned rescue submersibles and associated ancillary equipment for the UK, Australian, Indian, Chinese, Singaporean, South Korean, Vietnamese and Swedish navies.

FCL can offer a range of services in support of marine engineering projects, from substantiation of existing designs via the production of appropriate design-by-rule calculations and finite element analyses, through to complete turnkey solutions including front end engineering, weight optimisation, load case development, detailed design and fabrication drawing production.

Load case development is always carried out in close consultation with the client and regulatory authorities, and requires that a design specification be provided first to define the required operating parameters. Our experience of previous similar vehicles and of the requirements of regulatory authorities is then utilised to identify the most important loadings and to focus the load case development around these scenarios.

Weight optimisation can be aided by refinement of the load cases to avoid catering for unnecesarily conservative design conditions, but is predominantly achieved by the selection of high-strength materials and careful design optimisation to ensure that both stresses and deformations are maintained within acceptable limits.

Yes, we have provided assistance on multiple projects which have involved the refurbishment of existing rescue submersibles.

In some cases this has involved the design of replacement, upgraded components, while in other cases it has involved assessment of corroded structures to determine whether these remain fit for service. In addition, we have reviewed the design of several 'rescue seats' (escape hatches with a flat surrounding structure to which a rescue submersible may be docked) on larger submarines of varying age, to assess their adequacy for recue operations. This work was based on fabrication drawings where available, plus dimensional information obtained by physical survey.

To date, all the submersible hulls that we have worked on have been designed in accordance with PD 5500 and Lloyds Register Rules, while viewports have been designed in accordance with ASME PVHO. In the majority of cases, the vehicles have been 'classed' by Lloyds Register.