FCL have established a successful track record in the provision of engineering consultancy services to the UK nuclear industry dating back to the late 1980s and early 1990s when the emphasis was on safely extending the life of the ageing Magnox power stations at sites such as Bradwell, Dungeness and Hinkley Point.

This pedigree in the nuclear industry was achieved by the successful execution of numerous structural integrity assessments and seismic hazard studies on new and existing equipment installed at Magnox & AGR power plants and the THORP fuel reprocessing facility.

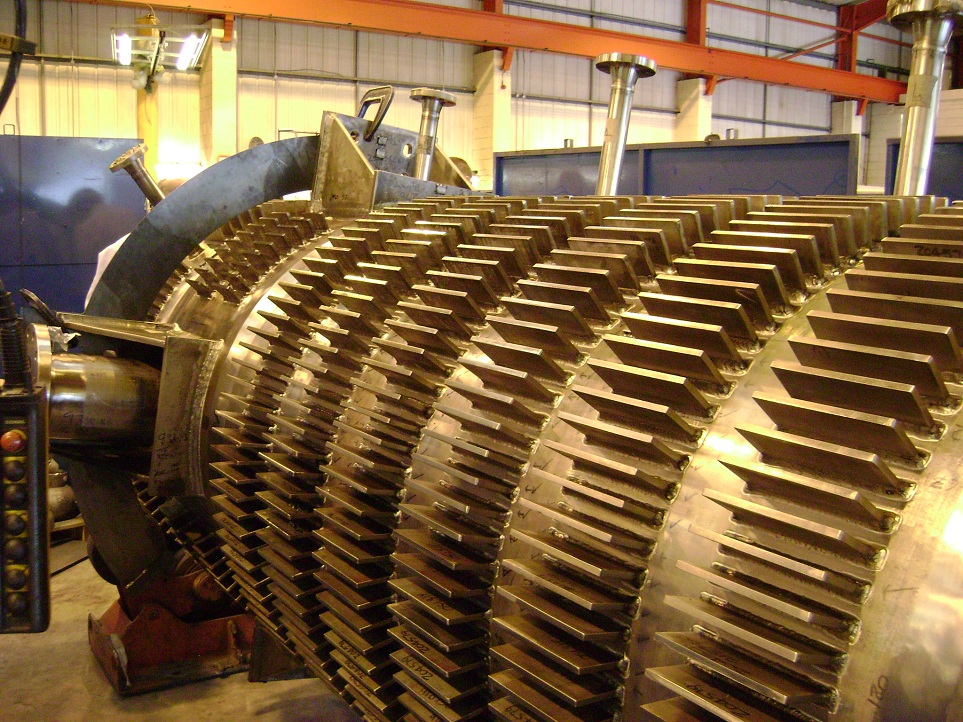

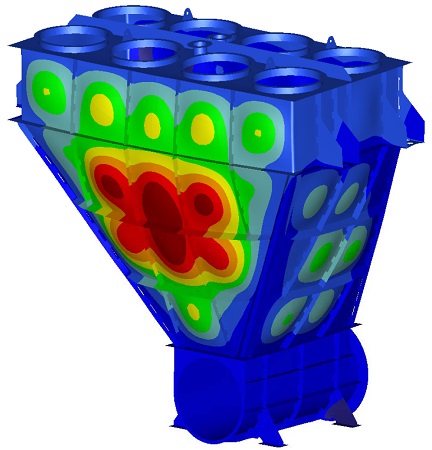

The wide range of project work that we have undertaken in recent years includes: seismic assessment of new “bottom line” steam boilers and ancillary equipment for Hinkley Point B and Hunterston B nuclear power stations; mechanical design and preparation of construction drawings for a replacement reaction section of a uranium hexafluoride (UF6) reactor vessel and a new HF kiln hopper installed at a UK nuclear fuel production facility; mechanical design and seismic qualification of vacuum insulated argon storage vessels for the Windscale Pile 1 Decommissioning Project; mechanical design and seismic qualification of cooling water strainers at the Lungmen & Ling-Ao Nuclear Power Stations; structural integrity assessment of pressurisers used in the production of AGR fuel pins; seismic qualification of nitrogen storage vessels at Dungeness B Nuclear Power Station; seismic assessment of RUHS frost protection condenser tube bundle at the Sizewell B Nuclear Power Station.

We believe that this range of experience represents a rare commodity which could potentially be put to good use as we look forward to the resurgence of the UK Nuclear power generation industry.

Case studies covering just three of the numerous projects undertaken by FCL in the nuclear industry can be viewed by clicking on the links below.