FCL staff can offer a wealth of experience in pressure vessel design combined with an in-depth understanding of the risk factors for fatigue in such equipment. This enables FCL to confidently undertake work for clients faced with the task of developing experimental new equipment capable of operating safely even when exposed to extremely arduous duties.

As an example, FCL were recently approached by a client seeking to develop an industrial scale reactor vessel capable of producing a special silicon-graphite powder used to manufacture the anodes in next generation lithium-ion batteries. At the outset, little more was known than the required internal volume, the process conditions and the fact that a full diameter girth flange was necessary to permit access to an internal mixer.

The batch type nature of the process means that the vessel would be subject to an onerous fatigue duty including large cycles in both pressure and temperature. An additional concern was the potential for environmentally assisted cracking and / or embrittlement due to the presence of elemental hydrogen in the process mix. Furthermore, the vessel needed to be temperature controlled via use of an external induction coil and forced cooling.

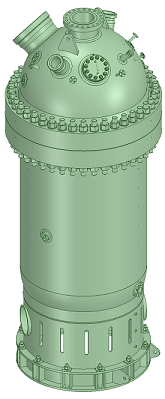

Despite the lack of information, FCL were quickly able to develop a design concept, initially providing different options in a shortlist of potential materials to assist our client in selecting the most pragmatic and cost-effective solution. fatigue resistant features such as a support skirt with forged 'Y' piece junction with the vessel and integrity reinforced nozzles with swept collars to permit butt-welding into the shell / heads were introduced from the outset, permitting the development of detailed fabrication drawings at a relatively early stage in the project, which proved extremely valuable in minimising overall timescales.

During the work, FCL also offered significant levels of assistance in developing an appropriate testing programme to confirm that the selected materials of construction offered satisfactory resistance to hydrogen embrittlement, which extended to offering advice on preferred welding methods to maximise the toughness of the deposited weld metal. Other design aspects addressed included reinforcement of the mixer mounting nozzle to ensure that this provided sufficient rigidity to permit the mixer blades to run close to the vessel shell without a risk of fouling, and consideration of the implications of potential sudden pressure 'spikes' due to runaway reaction.

Although the multinational nature of the project and selected plant location dictated that the final design was underwritten by others, the quality of the concept put forward was subsequently confirmed, with no significant issues identified during the design substantiation and approval process.