FCL’s experience in the application of design-by-analysis methods to pressure vessel design has often enabled us to provide a rapid and cost-effective appraisal of unusual design concepts, permitting our clients to introduce appropriate modifications at a timely point in the design process.

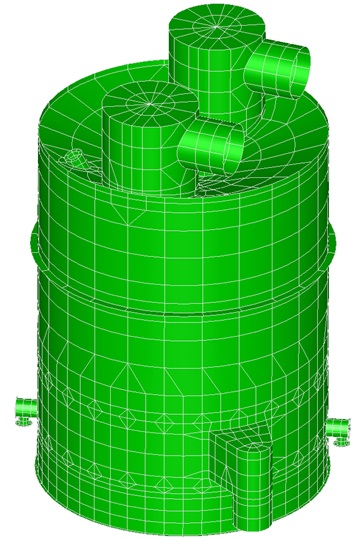

An example of such work involved the review of the design of a new vacuum pan, which was being developed by a major sugar refinery.

The proposed design incorporated a number of unusual features not fully addressed by design-by-rule methods, including an inverse conical roof with two large openings, a double-conical floor with central mounting for a mechanical agitator, an internal calandria and an unusual square-profile nozzle connection.

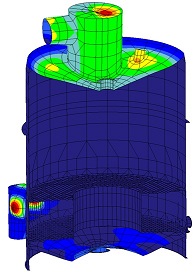

After preparing design-by-rule calculations to confirm the adequacy of the basic pressure envelope, FCL carried out a number of linear elastic analyses to provide a full understanding of the mechanical behaviour under various loading conditions including internal and external pressure, weight, contents inventory and agitator loading. In order to make efficient use of computational resources, this work was carried out using a relatively simple shell and beam element finite element model, which was developed using CREO/Simulate software.

The results were assessed against the requirements of PD5500 and indicated a number of weaknesses in the original design.

On the basis of these findings, FCL went on to recommend a series of design modifications including increases in the thickness of some items combined with the addition of an array of stiffeners on the top cone to reinforce the outlet nozzles.

With the benefit of this work, our client was able to proceed with final detailing of the vacuum pan in the confidence that the design was fundamentally sound.